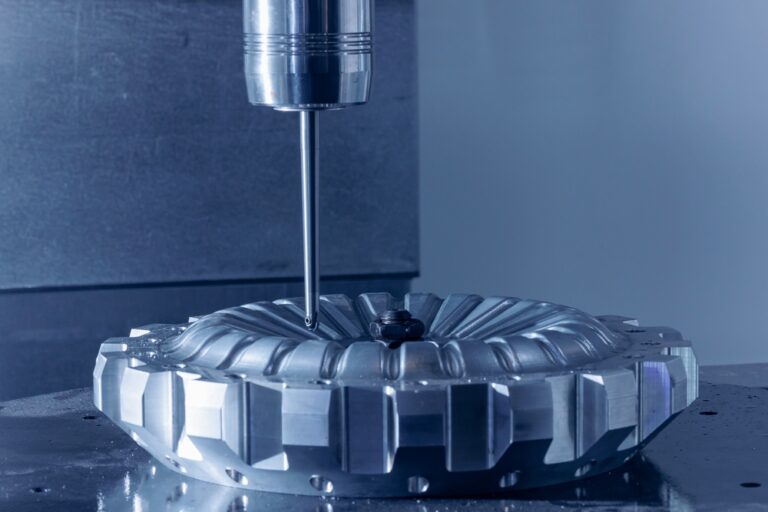

Eagle Alloys er klar til at omdefinere markedet for titanium færdige dele gennem en unik blanding af tilpasning, kvalitetshåndværk, og urokkeligt kundefokus. Beliggende i Tennessee, vi henvender os til en mangfoldig kundekreds, bygning af holdbare og højtydende titaniumkomponenter, der er skræddersyet til de specifikke krav i industrier såsom rumfart, medicinsk, bilindustrien, og forsvar. Vores engagement i innovation driver os til løbende at forbedre vores fremstillingsprocesser og produktudbud, sikre, at vi forbliver på forkant med industriens fremskridt.

Titanium applikationer: Alsidighed på tværs af brancher

Titaniums bemærkelsesværdige egenskaber gør det til et ideelt valg til en bred vifte af applikationer. I rumfartssektoren, dens lette, men stærke natur bidrager til brændstofeffektivitet og ydeevne i flydesign. Til det medicinske område, titaniums biokompatibilitet gør det muligt at bruge det i implantater og kirurgiske instrumenter, sikring af patientsikkerhed og produkters levetid. Bilindustrien nyder godt af titaniums modstandsdygtighed over for korrosion og høje temperaturer, gør den velegnet til dele, der kræver holdbarhed og pålidelighed. I forsvaret, Titaniums styrke-til-vægt-forhold understøtter udviklingen af avancerede våben- og pansersystemer. Mens vi fortsætter med at innovere, Eagle Alloys er dedikeret til at udforske nye applikationer, der udnytter fordelene ved titanium, fremme vækst og opfylde de skiftende krav fra vores kunder.

Titanium legeringer: Forbedring af ydeevne gennem materialeinnovation

Titaniumlegeringer er klassificeret i to primære kategorier: alfa (en) og beta (B) legeringer, hver tilbyder særskilte egenskaber egnet til forskellige applikationer. Alfa-legeringer, såsom Ti-6-4 (Grade 5), er kendt for deres fremragende svejsbarhed og høje- temperatur ydeevne, hvilket gør dem ideelle til rumfartskomponenter. Beta legeringer, som Ti-15V-3Cr-3Sn-3ÁI, er kendetegnet ved deres overlegne styrke og formbarhed, ofte brugt i applikationer, der kræver høj slagfasthed.

Desuden, titanium kan legeres med elementer som aluminium, vanadium, og molybdæn for at forbedre specifikke egenskaber. For eksempel, Ti-6-2-4-6 er en højstyrkelegering, der foretrækkes i rumfart for sin exceptionelle træthedsmodstand. Hver titanlegering er konstrueret til at opfylde præcise krav, at sikre, at Eagle Alloys leverer optimale løsninger, der er skræddersyet til industriens behov, samtidig med at vi bevarer vores forpligtelse til kvalitet og integritet.